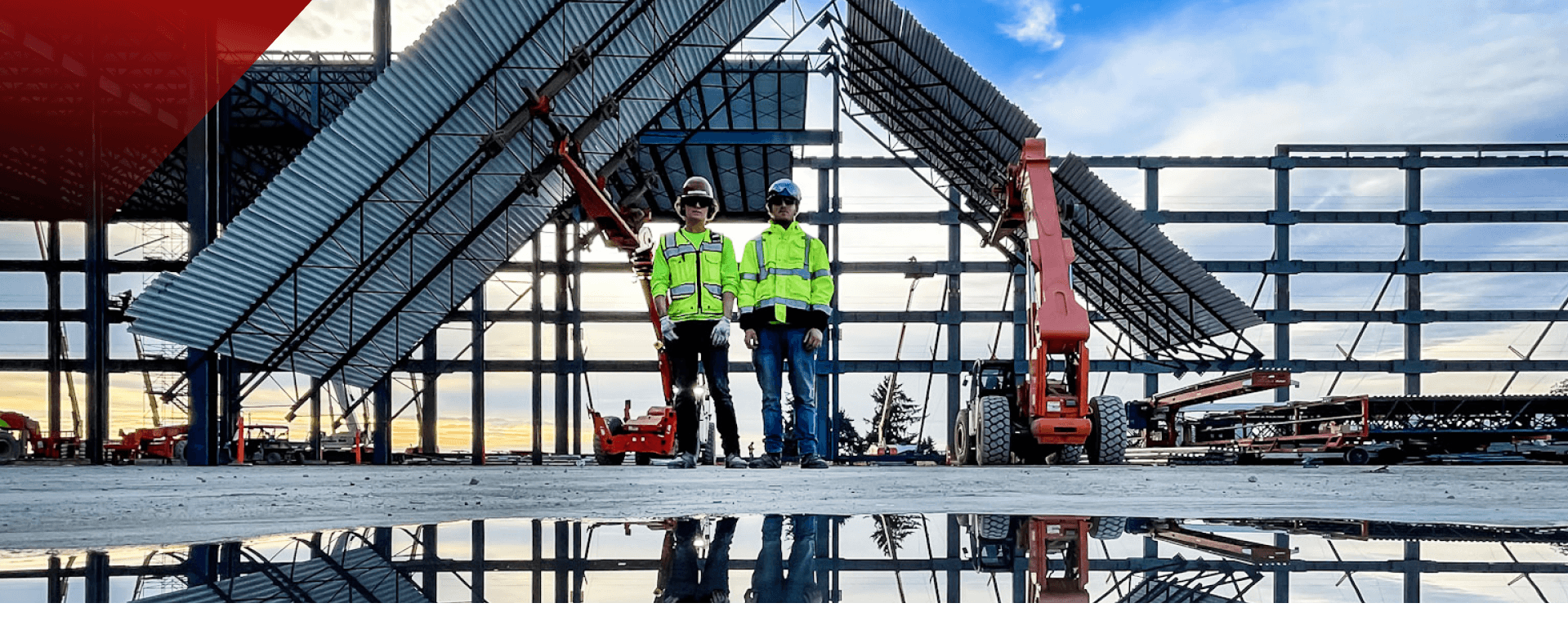

Safety

From the intensive training we do at Steeltech Academy to the proprietary innovations we develop and deploy with our teams, one thing is clear. BZI puts safety first. Period.

From the intensive training we do at Steeltech Academy to the proprietary innovations we develop and deploy with our teams, one thing is clear. BZI puts safety first. Period.

- 0EMR2017-2023

- 0Lost TimeIncident Rate

- 0TrainingCertifications

- 0Total RecordableIncident Rate

Investing in Excellence

How We Make Steel Work Safer

-

STEELTECH ACADEMY

Education and training are important to us. Throughout their tenure, team members regularly engage in safety, quality control, and leadership training courses provided by qualified instructors at our training facility, SteelTech Academy. Other focused training and certification programs include proprietary equipment such as the InnovaTech Panelization Systems, PPE, fall protection, forklifts, aerial lifts, and other tools and equipment standard for steel erection.

-

A strong safety culture

We are committed to helping our teams achieve quality and safety goals that meet or exceed industry standards. To do this, we provide qualified personnel, training, and other resources and oversee our Quality Management System (QMS). Our Quality Control Manual guides our employees to ensure our steel erection projects follow construction specifications and meet the AISC Certification Standard for Steel Fabrication and Erection. We maintain these systems to help improve our processes, keep our personnel safe, and promote growth in the quality of service.

-

Relentless Quality Control

With our shared work ethic and ideals, our team feels more like family than simply employees. Attitude, responsibility, and commitment to the team are only the beginning of what makes our organization unique. Safety is one of our core values, and to help solidify that, we’ve adopted “Thoughtful, Inspired, and Alert” as a phrase to keep it top of mind. With our emphasis on innovation, collaboration, and implementation the safety advantages of our panelization process are only compounded.